In 2012, following the adoption of the model Work Health and Safety Regulations, Australia began to transition to the Globally Harmonized System of Classification and Labelling of Chemicals (GHS), an international system used to classify and communicate chemical hazards.

The GHS was created by the United Nations in order to implement a single worldwide methodology for chemical classification, labeling and Safety Data Sheets (SDS). The system ensures that users are provided with practical, reliable and easy to understand information on chemical hazards, and can take the appropriate preventive and protective measures for their health and safety.

On the 26th of November 2016, Safe Work Australia announced that chemicals manufactured or imported before 1 January can continue to be supplied without needing to meet the labeling requirements under GHS.

SA, NT, QLD and NSW have adopted this system as of 1 January 2017 and other states will likely transition during 2017.

Peerless JAL has been manufacturing all goods as GHS compliant since 2016.

GHS

Under GHS, the threshold for communicating the hazards of products has been lowered so chemicals we have been successfully using for years will come with more information about the associated hazards.

The GHS uses pictograms, signal words, and hazard and precautionary statements to communicate this information.

Elements of the GHS

There are four main elements to the changes in hazard communication under the GHS.

1. Pictograms

There are nine hazard pictograms in the GHS which represent the physical, health and environmental hazards. The most common ones that you will come across in association with our products are:

The Corrosive symbol. This relates mostly to the ability of the product to corrode either skin or eye tissue. A product can be corrosive only to eyes, or to both skin and eyes. Either way, it will carry the same pictogram. If a product is classified under GHS as corrosive to skin it will also be corrosive under the ADG code (transport). This is not the same for the eyes.

The Exclamation mark pictogram covers a number of different hazard types including, but not limited to; acute toxicity (oral, dermal, inhalation), skin irritation, eye irritation and skin sensitisation. Peerless JAL products will be mostly be applied due to skin or eye irritancy.

2. Signal words

The GHS uses ‘Danger’ and ‘Warning’ as signal words to indicate the relative level of severity of a hazard. ‘Danger’ is used for the more severe or a significant hazard. In cases where the product is classified under both the Poison Schedule and the GHS, which occurs with products also used in the domestic sphere, the main signal word will continue to be ‘Caution’ or ‘Poison’.

3. Hazard and precautionary statements

Where previously the NOHSC classification system communicated hazards through ‘Risk’ and ‘Safety’ phrases, GHS talks about ‘Hazard’ and ‘Precautionary’ statements. As the names suggest hazard statements describe the hazard while precautionary statements recommended measures to minimize or prevent adverse effects. The GHS precautionary statements cover prevention, response, storage and disposal.

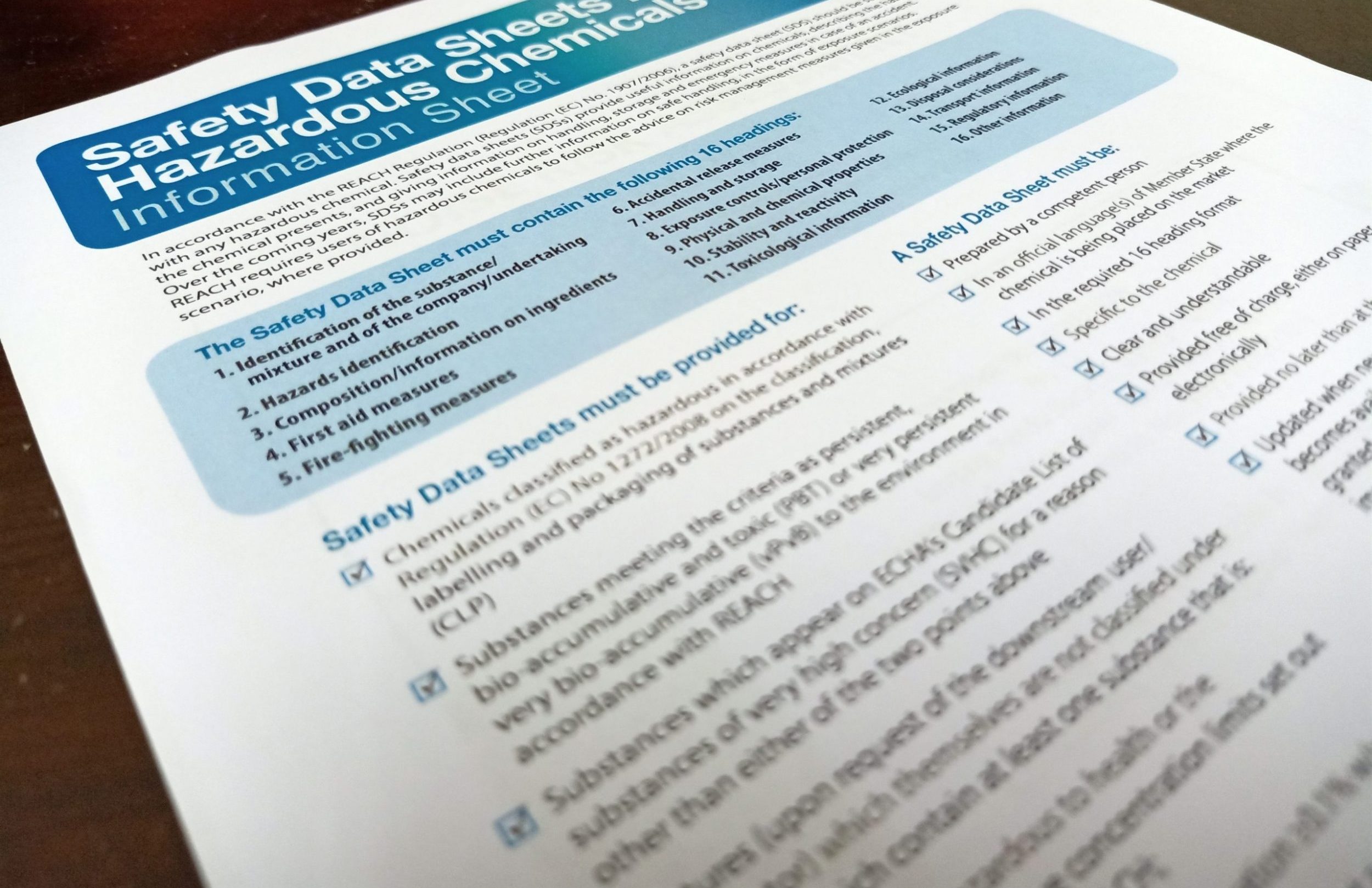

4. Safety Data Sheets (SDS)

Under GHS, material safety data sheets become SDS. The format and most of the information are very similar except for Section 2 which identifies the hazards involved. Here, risk and safety phrases have been replaced by the hazard and precautionary statements.

As we release the new products classified under GHS we are also distributing copies of the new SDS for each item. If you would like to receive our new SDSs in one batch please contact us.

All GHS compliant SDS is now available on the web site for download.

NPE and Phosphate free products

As part of our continuous improvement process for the GHS, Peerless JAL has taken the opportunity to make some exciting changes to the range.

All liquid products manufactured by Peerless JAL are now Phosphate and NPE free, below is an explanation of these items and why we have taken this opportunity to make these improvements:

Phosphates:

- Serve as a “builder” or chelating agent to improve cleaning efficiency.

- Builders, such as STPP (Sodium Tri Poly Phosphate), are important as they complex ions in Hard Water (Calcium and Magnesium) allowing the cleaning to take place.

- Chelating power minimises soap scum

- When phosphates end up in our lakes and rivers, they accelerate plant and algae growth. When the plants and algae die, the bacteria residue consumes the oxygen, leaving less for fish and aquatic life which need the oxygen to survive.

NPE:

- Nonylphenol (NPE) is considered to be an endocrine disruptor due to its ability to mimic estrogen and in turn disrupt the natural balance of hormones in affected organisms.

- The effects of NPE in the environment are most applicable to aquatic species. NPE can cause endocrine disruption in fish diet the most significant source of exposure of NPE to humans. Seafood in particular was found to have a high concentration of NPE.

- There is currently no regulation in Australia with regards to NPE.

Compliance implications and

product performance

As per the above, you will find a formulation that has been used for many years will now be classified as a Dangerous Good under GHS resulting in increased storage and compliance regulation of the Peerless JAL products you are using.

Peerless JAL has reformulated many of our best-known products to reduce hazard classification and in the process were able to actually improve the performance of many of them at the same time.

Below is an example of some of these improvements:

| PRODUCT | CHANGE/ IMPROVEMENT |

|---|---|

| ACTIV O SPRAY AND WIPE | REDUCTION IN HAZARD LEVEL/ IMPROVED PERFORMANCE |

| VITALITY WASHROOM MAINTAINER | REDUCTION IN HAZARD LEVEL/ IMPROVED PERFORMANCE |

| VERSADET NEUTRAL FLOOR CLEANER | REDUCTION IN HAZARD LEVEL/ IMPROVED PERFORMANCE |

| STATUS GLASS CLEANER | REDUCTION IN HAZARD LEVEL/ IMPROVED PERFORMANCE |

| S-CLEAN SANITISER | REDUCTION IN HAZARD LEVEL/ IMPROVED PERFORMANCE |

| ONE SHOT THICK TOILET BOWL CLEANER | REDUCTION IN HAZARD LEVEL |

| ACTIV SRA H/D SOIL REMOVER | REDUCTION IN HAZARD LEVEL/ IMPROVED PERFORMANCE |

Source: http://www.safeworkaustralia.gov.au/sites/swa/news/pages/05122016-labelling-requirements